Can You sublimate On Cardstock | Printing On Glitter & Laminated

Did you know over 70% of crafters have tried sublimation on various materials, but aren’t sure to answer can you sublimate on cardstock? Because cardstock is not mainly created for sublimation. But Yes! It can be sublimated if it has a coat of polymer. A type of plastic coat to absorb the sublimation ink. However, according to the crafters, we can use glitter cardstock for sublimation, because the glitter is a polymer-based material that can absorb sublimation ink even if it doesn’t have a polymer coat.

Check Sublimation On Glass.

Can You Sublimate On Cardstock?

The answer is, technically, no. But the cardstock can be sublimated either it should be a glitter cardstock or laminated with the thermal laminating pouch. The thermal laminate pouch will protect the cardstock from burning during the heat press plus it can absorb sublimation.

Cardstock, being paper-based, simply can’t handle those high temperatures without burning or warping.

Check How To Do Sublimation On Acrylic.

What Kind Of Cardstock Is Used For Sublimation

The ideal cardstock for sublimation should be able to withstand high heat and pressure, typically around 400°F. I’d recommend using high-quality white glitter cardstock for making various decoration pieces. Make sure to use heavy glitter cardstock, as I utilized 65 lbs.

Check Sublimation On Canvas.

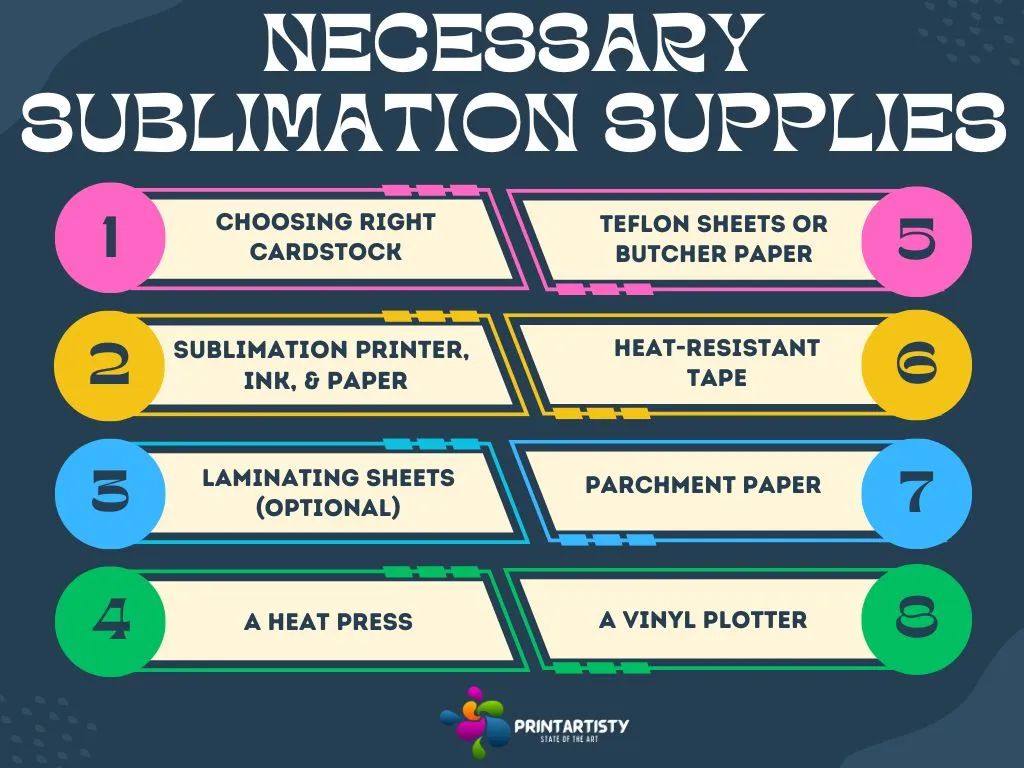

Necessary Sublimation Supplies

From the right type of cardstock and a good sublimation printer to inks, paper, and potentially laminating sheets, each supply plays a crucial role.

1. Choosing Right Cardstock

Not all cardstock is created equal, some are too thin, while others don’t handle heat well. Your best bet is to choose a heavyweight.

Check Sublimation On Wood

This type can withstand the intense heat of the sublimation process without warping or discoloring. Make sure it’s also bright white glitter to ensure vibrant color transfer.

Lastly, always do a test print before launching into your project. This way, you can ensure the cardstock performs as expected. You can choose White Glitter Cardstock – 10 Sheets Premium Glitter Paper and White Glitter Cardstock

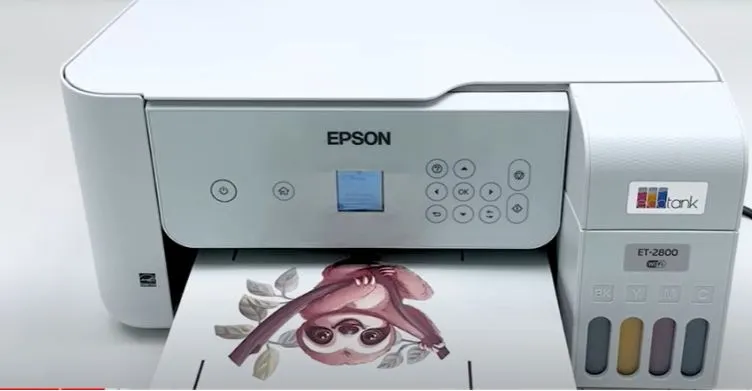

2. Sublimation Printer, Sublimation Ink, & Sublimation Paper

There are three essential supplies you’ll need for successful sublimation on cardstock: a quality sublimation printer, the right sublimation ink, and suitable sublimation paper.

Check Best Sublimation Paper.

A sublimation printer, like the Epson ET-15000 ET-8550, or ET-2800 is designed specifically for sublimation printing ensuring high-quality prints. But to be honest my favorite pick is ET-8550 because it truly shines out of many sublimation printers in terms of print quality.

Check Best Epson Sublimation Printers

Then, there’s the sublimation ink. I’d recommend Hiipoo’s sublimation ink for both, ET-15000 and ET-8550 also for ET-2800. Though ET-8550’s Hiipoo inks are available in 6 colors.

Lastly, the sublimation paper. I suggest A-SUB or HTVRONT’s sublimation paper as it’s designed for heat transfer and can hold onto the ink well.

These three essentials aren’t just random choices; they’re based on my personal experience and the positive feedback from others in the sublimation community.

Check Sublimation On Metal

3. Laminating Sheets (optional)

These sheets aren’t always necessary. Because they are used when you’re not desiring to use glitter cardstock. So you can make this product as an optional for you.

4. A Heat Press

There’s a variety of heat presses available, from smaller models for hobbyists to larger, industrial-grade ones for businesses. What’s important is that it reaches the appropriate temperature (around 400 degrees Fahrenheit) and exerts enough pressure to ensure a quality transfer. If you’re out of budget, you can choose the Cricut EasyPress because it is less expensive and portable too.

5. Teflon Sheets Or Butcher Paper

Both serve as a protective barrier between the heat press and the cardstock, preventing ink bleed-through and ensuring a clean transfer. Teflon sheets are reusable, heat-resistant, and provide a smooth, non-stick surface.

Check How To Do Sublimation On Ceramic Tile

On the other hand, butcher paper is cheaper and disposable. It’s less durable but effectively absorbs excess ink during the sublimation process.

6. Heat-resistant tape

This special tape is designed to withstand high temperatures without melting or leaving residue on your project.

It’s important to use heat-resistant tape when taping your design to the cardstock. It ensures the design does not leave its place during the heat press process. If you use regular tape, it’ll melt and ruin your work.

7. Parchment Paper

It’s indispensable when it comes to protecting your sublimation blanks and heat press. Here’s why:

During sublimation, the ink turns into gas. Some of this gas can escape and end up on your heat-press, staining it. By placing it between your design and the heat press, you prevent stray ink from dirtying your equipment.

Check Can You Sublimate On Rayon

It can also protect your sublimation blanks from scorching. It’s a simple, cost-effective way to ensure a clean, professional finish every time.

8. A Vinyl Plotter

I utilize Cricut Maker for print then cut features. Because Cardstock’s custom designs will require print then cut feature to bring sophistication to the designs.

How to Sublimate on Cardstock Step-By-Step Guide

Let’s get right into the process of sublimating on cardstock.

1. Sublimation Printer Paper Settings

First, ensure your printer is on the correct setting for sublimation paper. This is typically a high-quality or photo-quality setting.

Next, adjust the paper size to match the size of your cardstock.

Check Sublimation On Stainless Steel

Now, set the paper type to cardstock or heavy paper, if available. If not, a thick or matte paper setting will usually work. But my recommended sublimation printers, ET-15000 and ET-8550 both have the option of heavy paper.

Lastly, adjust the print quality to high. This ensures your design will be vibrant and sharp on the cardstock.

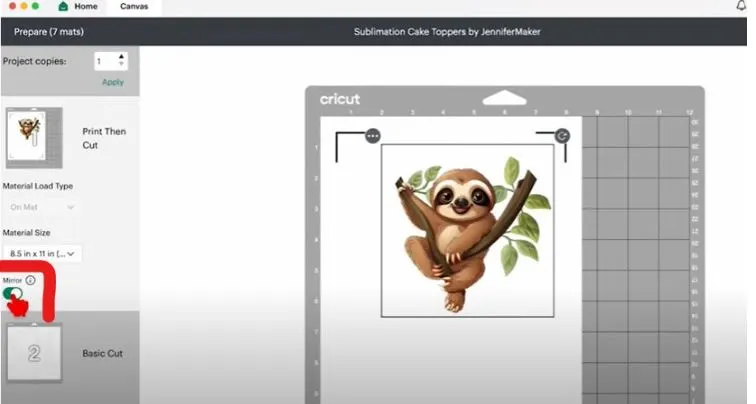

2. Prepare The Design & Mirror It

The design must be clear, concise, and visually pleasing. I use design software, like Adobe Illustrator, to create or edit my designs. You can check the free design softwares for sublimation. You can also use Cricut’s Design space.

Once you’re satisfied with the design, ensure it’s mirrored or flipped horizontally. This is crucial because the design will be transferred in reverse onto the cardstock. Not flipping the design could result in a final product that’s backward. You can also mirror the design before hitting the Print, simply from the printing preference.

Make sure the sublimation printer is loaded with sublimation ink, then place the sublimation paper in the printer tray.

Next, open the design on your computer and select ‘Print’. In the printer settings, I choose the correct paper size and print quality. I usually opt for ‘High Quality’ to get the best results.

3. Print Then Cut

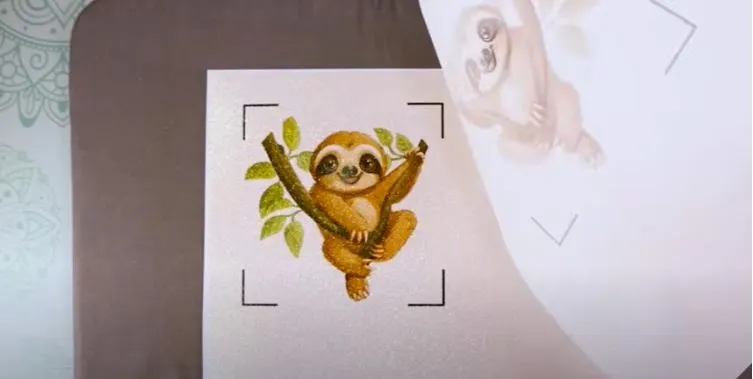

Once you’ve done with the design. Then your printer should be connected with the Cricut Maker. Upload your design in the Cricut Design Space select the “print then cut” feature and print the image.

Check Sublimation On Faux Leather

4. Cutting

Once you’re done with the printing, get the Cricut Mat and place the printed sublimation paper on it. Load it to the Cricut Maker to cut the design precisely. If your design is only just a picture then you don’t need any cutting machine.

After cutting the printed sublimation paper, load the cardstock in the Cricut Maker to cut the same design. Another tip is you can cut the sublimated cardstock after heat pressing as shown in the picture below.

5. Heat-Pressing

Moving on to the heat pressing stage, get your heat press ready to transfer the design from the sublimation paper onto the cardstock.

First, preheat the press to about 400 degrees Fahrenheit. It’s crucial to ensure the press reaches the correct temperature for successful transfer.

Next, position the sublimation paper with the printed design facing downward onto the pre-cut cardstock, and use heat-resistant tape to secure it in place. Cover it with the butcher or Teflon sheet above.

Close the heat press and let it work its magic for around 45 seconds. If the temperature is too high, you’ll risk damaging the cardstock or fading the colors or they may turn into yellow. Similarly, if you press for too long, the cardstock might burn, but if you don’t press long enough, the image won’t be transferred effectively.

After pressing your image, let the cardstock cool down properly to ensure the best possible final results. I’d advise giving it a good few minutes.

Once cooled, you’ll notice the colors are more vibrant, and the image has a smooth, glossy finish.

If you peel off the transfer paper too soon, the image mightn’t fully adhere to the cardstock, which can result in a faded or distorted design.

Voila! The design is now perfectly transferred onto the cardstock.

Can You Laminate Cardstock And Then Sublimate It?

So, can you laminate cardstock and then sublimate it?

Yes, you absolutely can.

Let’s start by understanding the process of laminating cardstock.

Laminating Cardstock: Process

Yes, you absolutely can laminate cardstock!

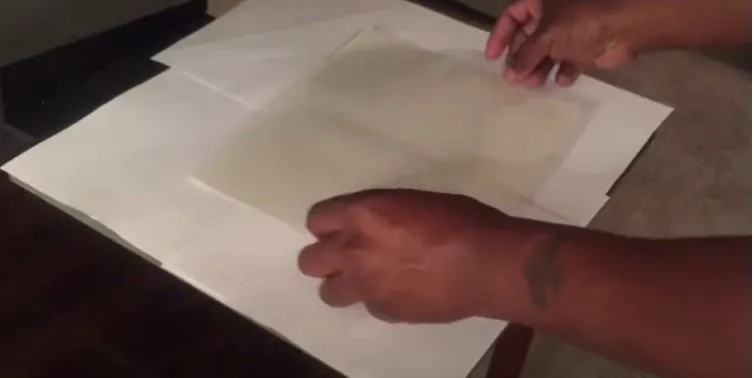

First, you’ll need a laminating machine which is optional, you can use a heat press too, and laminating pouches.

Place your cardstock inside the pouch, making sure it’s centered. Then, feed the pouch into your laminating machine. It might take a minute or two. Once it’s done, you’re left with a beautifully laminated piece of cardstock. I recommend using a heat press as you can save the 1 piece of lamination sheet and the laminating machine itself.

Just heat press the lamination sheet for 15 seconds onto the cardstock’s side that you’d be sublimating.

Sublimation After Lamination

Technically, it’s possible. You see, lamination can sometimes interfere with the sublimation process. The heat from the sublimation can cause the lamination to bubble or peel, ruining your design. If you want to try this, you need to be careful with the heat settings of your sublimation press.

Expected Results

Start by laminating your cardstock using a standard laminating machine. Make sure it’s completely cooled before moving on to the next step.

Then, print your image with sublimation ink onto sublimation paper.

Position this paper on your laminated cardstock, and then press it using a heat press.

The heat will cause the ink to turn into a gas, which will then be absorbed by the laminate on the cardstock.

When done correctly, you’ll end up with a vibrant and long-lasting image on your cardstock.

Can You Use Cardstock In A Sublimation Printer?

I should mention that you can indeed use cardstock in a sublimation printer. However, the results won’t be as vibrant or long-lasting as when you use sublimation paper. Still, if you’re in a pinch or experimenting, cardstock can work. Because sublimation ink’s actual colors are exposed after heat pressing.

So printing directly on the cardstock using sublimation ink is not recommended. However, you can use cardstock to print. The printer should not be a sublimation printer using sublimation ink.

But it should be a regular printer. Sublimation ink will not work in the regular printer. So it should be a regular printer and regular ink. You can further read: Can you use sublimation ink for regular printing.

Can You Sublimate On White Cardstock

It is recommended to use only white cardstock for sublimation tasks. Though various colors of cardstocks are also available the sublimation ink will work on the light colors.

The durability of white cardstock can be a plus point. It holds up better to handling and doesn’t tear as easily. It’s especially handy if you’re creating items like bookmarks or business cards.

Final Thoughts

sublimating on cardstock can be unique than other sublimation blanks. It can be used for cake toppers, scrapbooks, gift tags, educational materials, and much more. The vibrant, lasting colors that sublimation provides can breathe new life into otherwise ordinary cardstock projects.

Furthermore, investing in quality sublimation inks and a reliable heat press will greatly increase your chances of creating vibrant sublimation prints. But make sure to use the correct weight, color, and texture of the cardstocks.