How To Make Printer Ink Permanent On Fabric | 5 Useful Tips

If you do not execute the t-shirt printing properly then the ink from the fabric might get off. To ensure achieving impressive results for a long time, you must need to consider the durability and longevity of the prints. You’ll find various ways to customize apparel including DTF, DTG, heat transfer paper, heat transfer vinyl, and so on out there. But not all methods of t-shirt printing are prominent for their durability. So today we’ll provide some useful tips on how to make printer ink permanent on fabric.

How To Make Printer Ink Permanent On Fabric

If you’re using sublimation ink to print on t-shirts or other fabric then you won’t need to use any kind of chemicals to ensure durability. Because the sublimation printing technique is the most durable process of customizing apparel and is permanent due to adherence of the ink inside the fabric pores.

Apart from that, many enthusiasts use heat transfer paper and vinyl which isn’t durable as the sublimation is. So we use several methods including using a fixative spray and freezing paper.

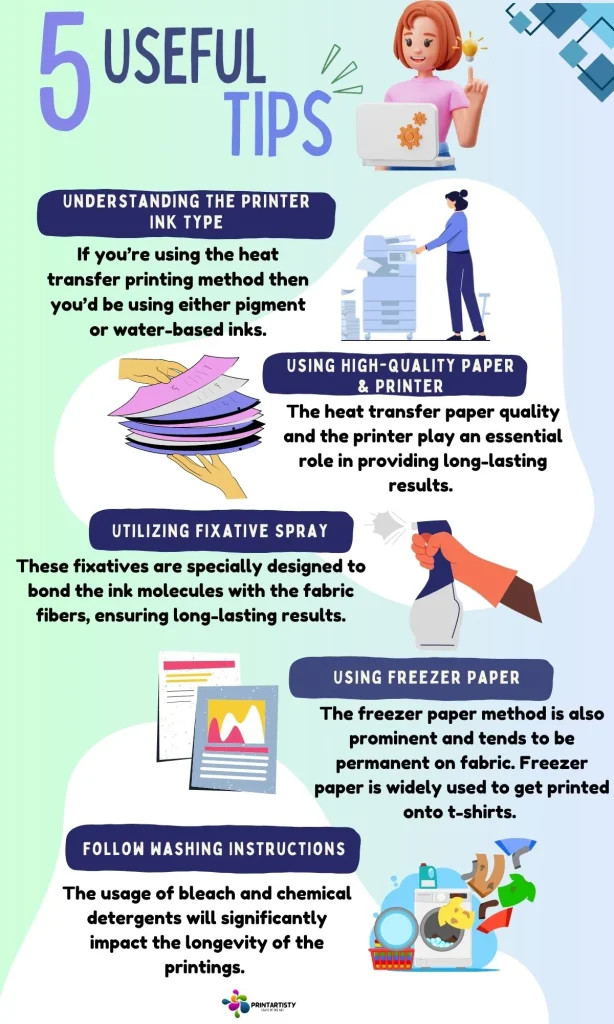

1. Understanding The Printer Ink Type

If you’re using the heat transfer printing method then you’d be using either pigment or water-based inks. Water-based inks aren’t durable as the pigment is. Because pigment has microscopic particles that are adhered to the top of the apparel’s fibers, making the ink long-lasting, water, and fade-resistant.

On the other hand, DTF, DTG, screen printing, and sublimation use their particular type of inks which are also long-lasting and permanent. But heat transfer paper and printable vinyl will require either pigment or water-based regular inks. So it is essential to understand which durable printer ink you’re using.

2. Using High-Quality Paper & Printer

The heat transfer paper quality and the printer play an essential role in providing long-lasting results. Make sure you’re using the heat transfer paper designed for the compatible fabric. Because you’ll find different types of heat transfer papers for particular color fabrics. Also, ensure to use compatible heat transfer paper that is designed for the particular printers.

This way you’ll get the dazzling final results that will be permanent on the fabric. Because compatible heat transfer paper and the best printer for heat transfer t-shirts ensure you provide correct results without any mess of removing or fading ink. Lastly, heat press pressure and time also need to be considered when intending for the best results. Make sure to use even pressure and temperature in order to get the design bonded with the fabric.

3. Utilizing Fixative Spray

By following the above tips, if you’re still concerned about the results then use a fixative spray. These fixatives are specially designed to bond the ink molecules with the fabric fibers, ensuring long-lasting results.

Before spraying the fixative, prepare the fabric by washing it without fabric softener or any bleached chemical. This will ensure the removal of any lint or dust particles that might hinder the ink’s adherence properly. Once the fabric is ready, print the t-shirt and get the flat surface or heat press and lay the t-shirt down on the surface.

Apply the fixative over the printed t-shirt evenly and heat press it for a couple of seconds. You need to make sure to use a fixative spray that is suitable for the printing technique you’re utilizing. The fixative that requires heat to get dried is the heat fixative and is the most durable.

4. Using Freezer Paper

The freezer paper method is also prominent and tends to be permanent on fabric. Freezer paper is widely used to get printed onto t-shirts. The ink is printed to the fabric using freezer paper as a transfer medium. This method works well with both inkjet and laser printers.

Wash your t-shirt with sodium carbonate or washing soda. This will remove any residue and ensure the fabric accepts the ink permanently. After washing dry it thoroughly before printing.

Now print on the freezer paper, you should know freezer paper has a heavy coat of wax that tends to melt while heat pressing. Print onto the shiny side and let the ink dry completely. Additionally, make sure that the print quality is set to “BEST” and the printer settings are “THICK”.

Once the paper is printed, use the lint roller to clean the t-shirt and place the freezer paper over the t-shirt where you exactly want to have the design. Set your iron or heat press to the appropriate heat setting and carefully press it over the freezer paper. Peel off the freezer paper when the transfer is finished, revealing the fabric’s permanent ink image.

Note: Test the methods on a small piece of fabric or scrap before applying them to your final t-shirt.

5. Follow Washing Instructions

The usage of bleach and chemical detergents will significantly impact the longevity of the printings. It is recommended always to follow the manufacturer’s guidelines when washing the fabric with detergents.

Is Inkjet Ink Permanent On Fabric?

Inkjet ink is typically water-based and may not be inherently permanent on fabric. If it is pigment then it would be permanent. It has the potential to fade or wash out over time especially if you don’t follow the washing instructions. However, there are useful tips that can be utilized, such as using fixatives or heat-setting techniques, to enhance the permanence of inkjet ink on the fabric.

What if you’ve tried different ways to keep the t-shirt prints permanent but still the inkjet print is peeling? Here is the solution read the article: How to fix peeling shirt printing or iron-on transfers.

Conclusion

Whether you want to print fabric for yourself or for a project, achieving long-lasting and vibrant results on fabric is a top priority. By exploring the above mentioned-ideas, you can have remarkably robust prints. From understanding the printing medium to following the washing instructions, your fabric design will last until wear and tear. As you embark on your fabric printing journey, remember to experiment, test, adapt, and explore the possibilities.