Sublimation On Cotton T-Shirts Without Spray | 100% Cotton

Sublimation brings vibrant results on polyester that doesn’t mean you can’t do sublimation on cotton. Yeah! You can sublimate on cotton but the natural fibers cannot be directly sublimated because they don’t bind with sublimation ink. Instead of sublimating directly onto the cotton, we had to utilize the various indirect ways and found the two effective ways that provided long-lasting and cost-effective results. So let’s dig down into the utilized methods.

Sublimation On Cotton By Utilizing 2 Methods

My preferred method is using Siser EasySubli HTV which is a durable and vibrant method as I got similar vibrant results with polyester. Although It involves a couple of more pieces of equipment so it may seem expensive to beginners. But how can I ignore novices’ crafting hobby?

In alternative to the expensive method, I prefer using a dyepress poly-t plus spray on a cotton towel or t-shirt to sublimate but as it is a cost-effective method so I cannot guarantee that it will last longer and won’t wash out. But yeah! There is something that you can rely on this method and that is why I’ve tried it.

Method 1: Using Siser Easysubli With Sawgrass or Epson Printer (Preferred)

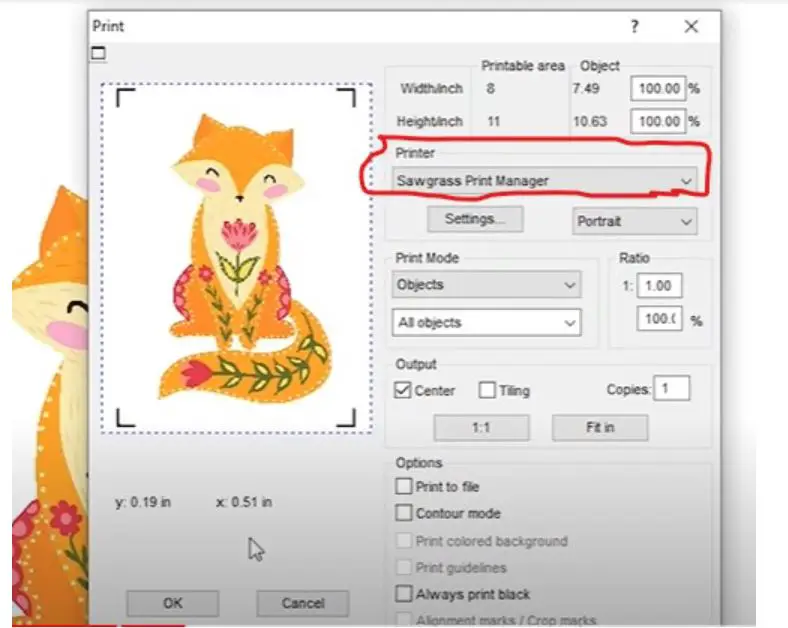

Why I prefer Sawgrass SG500 over Epson Ecotank is Sawgrass will allow you to print on heat transfer vinyl from the Sawgrass print manager. Although you can use an Epson sublimation printer too Sawgrass does its job precisely according to the material of the substrate also it enhances color correction.

Supplied Required:

Step-by-Step Guide:

Step 1: Calibrate With Cricut

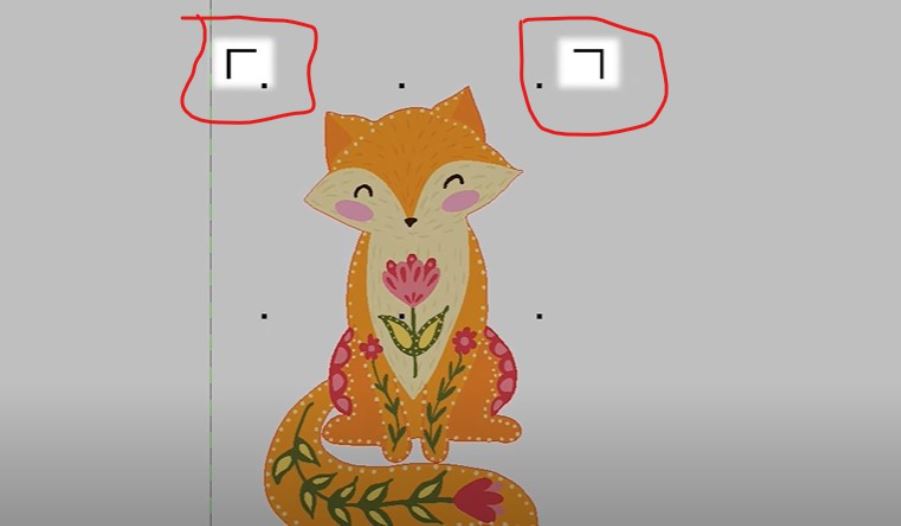

The first step you need to do is calibrate your printer with a vinyl cutter. I’m a regular user of the Cricut vinyl cutter but this time I’ve given a try to the GCC vinyl cutter a. You can use a silhouette vinyl cutter too which is an alternative to the Cricut. After calibrating, import your design into the software you’re using.

Important note: Siser EasySubli will have 2 sheets. One sheet is the print sheet which we’ll use for printing and weeding purpose and the second is the transfer sheet to use while heat transferring. We’ll feed and print the print sheet using sawgrass.

Also, ensure to turn on the registration marks on the image to trace the image precisely. Additionally, GCC also requires printed registration marks around the image to cut.

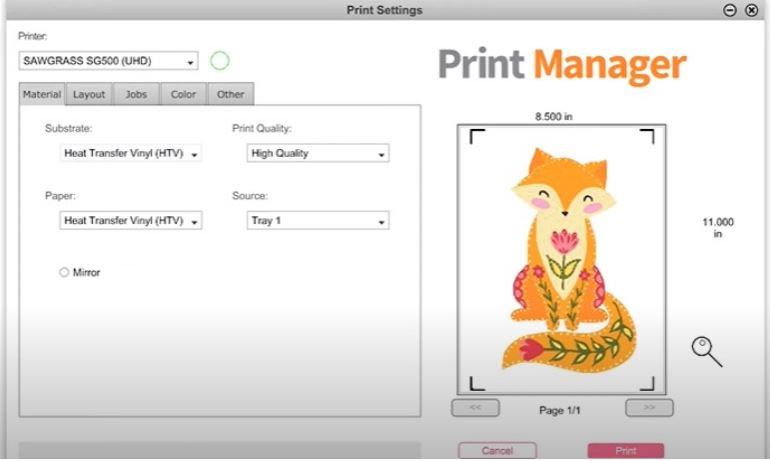

Step 2: Print Using Sawgrass

After design import and set, print the design using a sawgrass printer.

Now the next step is to set the print substrate as heat transfer vinyl from in the sawgrass print manager and ensure to uncheck the mirror option. Because we’re not gonna transfer the printed side facing to the substrate. Once the mirror is unchecked, hit the print button to print the design.

Step 3: Printing

After printing the design, the paper might be wet so we’ll cure the printed sheet. Place the printed sheet underneath the heat press and hover the upper plate of the heat press but ensure the heat press upper plate should be a few inches above the printed paper. We’ll only hover over the printed sheet for a couple of seconds at medium temperature.

Step 4: Cut The Design

After curing, place the printed sheet on the cutting mat and load it into the vinyl cutter, and start cutting the sheet.

Step 5: Weed & Transfer

After cutting the design, you can weed the cut design using a weeding tool or weed with your hand from the corner. After weeding the printed sheet, peel off the transfer sheet’s backing and apply it to the weeded image. Press it firmly using a squeegee or a credit card.

Step 6: Peel off the transfer

After applying the transfer sheet firmly, turn over the backside of the transfer sheet and remove the printed sheet from the corner and peel off the transfer sheet slowly therefore the printed design will be transferred onto the transfer sheet.

Step 7: Ready To Sublimate

Set the heat press setting for Siser Easysubli that is 15 seconds, temperature 311F, and medium pressure. Once the heat press is ready place the cotton t-shirt underneath the heat press and places the transfer sheet facing down the white transfer side. Cover with butcher paper and start pressing.

Step 8: Final Result

After the required time, pull the heat press and peel off the mask slowly. Ta-da.

Method 2: Using A Poly-T Spray (Affordable But Not Durable As Siser EasySubli)

Now, this method requires pretreatment or curing of the fabric before getting sublimated. So we’ll show you how to cure cotton for sublimation.

Supplied Required:

Required Supplies For Pretreatment

Step By Step Guide:

Step 1: Prepare Concentrate

To make the mixture, take the 4 ounces of concentrate and add 12 ounces of water to the spray bottle of 16 ounces. Shake well and the spray is ready.

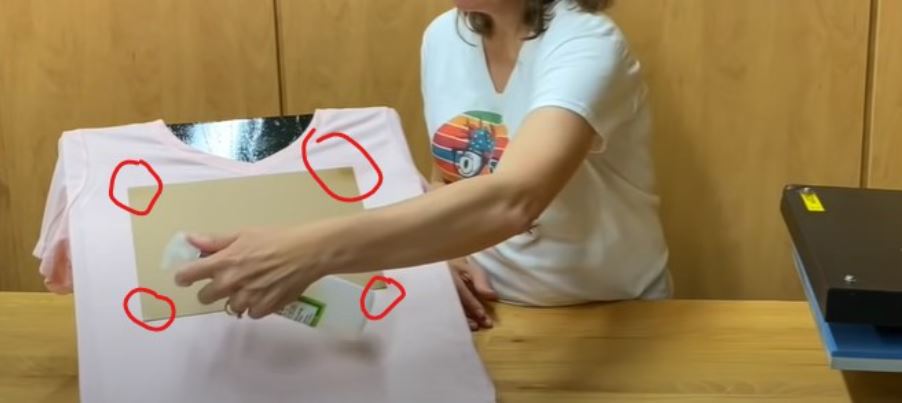

Now place the cardboard in between the t-shirt and also take another piece of cardboard and place it over the center of the t-shirt where you’re gonna sublimate your image. After placing, spray each corner of the cardboard to make the marks for spraying on the t-shirt.

Spray the t-shirt thoroughly until it gets dampened.

Step 2: Heat press

Now put the t-shirt beneath the heat press, place the parchment paper, and press it for 40 seconds at 330F. Once it is done then it’s time for the second coat. Also, you’ll observe the steam will be coming out of the heat press. Now the second coat will be lighter damp in comparison to the first coat. Now spray it again in the same area.

Step 3: Heat Press Again

After the second time spraying, press the shirt by placing the parchment paper. And this time we’ll cure it for 20 seconds only. Now the cured cotton shirt is ready to be sublimated.

Step 4: Print The Design

Now, print the design using your sublimation printer and place it on the cured area of the t-shirt. Secure it with heat-resistant tape, place the parchment or butcher paper, and press it for 70 seconds, medium pressure, and 385F. Alright! Our vibrant sublimated cotton t-shirt is here.

Ways To Sublimate On Cotton

Apart from my precise cotton sublimation methods, I found some other hectic ways to bring into being the sublimation of cotton.

However, I really don’t admire trying out these methods except white glitter HTV. Because the other two methods seem to be hard for me being an experienced crafter. So my chosen methods are simplified and you can try them for DIY or business-selling purposes.

Will Sublimation Wash Out Of Cotton

Well, sublimation is a true chemical process to bond with the synthetic fibers and if you use cotton without curing then sublimation will likely to be faded or wash out of the cotton. Although sublimation ink is also bonded with the polymer coat on the t-shirt, not with the cotton. So if the coat is removed then the ink will also be washed out.

Can You Sublimate On 100 Cotton

Yes, you can sublimate on 100% cotton t-shirts but not directly onto the fabric. You will need to follow either the Siser HTV process or the poly coat method. Both are durable but the SIser HTV is preferred because it is a versatile and robust method that also eliminates the color limitation. I have also reviewed the Siser HTV in the best sublimation paper for dark shirts.

Conclusion

Utilize these two methods and you won’t regret it. Whether it is your printing project or you want to sublimate your family member’s cotton t-shirt, you can easily sublimate on cotton with a couple of steps. Never ever I would suggest sublimating on direct cotton. Because the sublimation ink won’t bond with it and your hard work DIY will be ruined after a single wash.