DTF Vs Sublimation: Which One Is Better?

You probably have heard the term sublimation printing and DTF printing. But you don’t know the core differences between sublimation and DTF because you’re a beginner and confused that which printing method is the best when it comes to starting a lucrative business. Both methods are robust to print fabrics. But both are different from each other.

They both have pros, and cons, equipment pricing differences, process, and printing robustness too. So let’s dig into the DTF Vs Sublimation debate in detail today.

What Is The Main Difference Between Sublimation vs DTF

The main difference between sublimation and DTF is that sublimation involves a sublimation paper to transfer the sublimation ink onto the fabric or substrate, it becomes a permanent part of the substrate because the sublimation ink turns into gas after heat transfer.

On the other hand, DTF is a two-step process in which a transfer film is printed via an inkjet printer and then transferred onto the fabric using a heat press thus forming a layer of ink over the top.

They both require different types of printers, ink, and paper. However, the only similarity between the equipment is using a heat press. They both require a heat press to transfer the printed image onto the substrate. Despite that, their transfer temperature and time are different.

How Does Sublimation Printing Work?

The sublimation process is a simplified method in which you print using a sublimation printer and sublimation ink on a special type of poly-coated transfer paper called sublimation paper. And then the printed sublimation paper is placed over the surface of the polyester t-shirt and heat-pressed to transfer the design onto the substrate. You may check the best sublimation printer for heat transfer.

When the sublimation paper is heat pressed, the ink on the sublimation paper turns from solid to a direct gaseous state by eliminating the liquid phase, and actually, after changing the state, it again turns into solid. This way, the sublimation ink is embedded into the fabric or substrate and becomes a part of them. It will never be peeled off or faded.

Unlike DTF, heat transfer, and DTG, sublimation never leaves a layer over the top that is prone to peeling off or cracking. Also, you can check DTG vs sublimation comparison.

How Does DTF (Direct to Film) Printing Work?

On the other hand, DTF is a bit complicated and requires a couple of steps to do the printing. DTF involves printing on a special film using inkjet technology DTF printer later on it is heat transferred via a heat press. First of all, a design is prepared and printed on a special transfer film, the printed transfer film is then coated with an adhesive transfer powder.

Next, the coated transfer film is heat pressed in order to melt the adhesive powder. The heat-pressed transfer film is placed on the piece of garment and again heat-pressed to transfer the design. The transfer film is then peeled off and again the printed t-shirt is heat-pressed one more time to ensure the durability of the design. This way, the ink will be completely cured in the fabric increasing the life of the printing.

Unlike sublimation, DTF forms a layer over the top of the substrate that can be prone to cracking if the fabric or substrate is not washed according to the precautions.

Detailed Differences

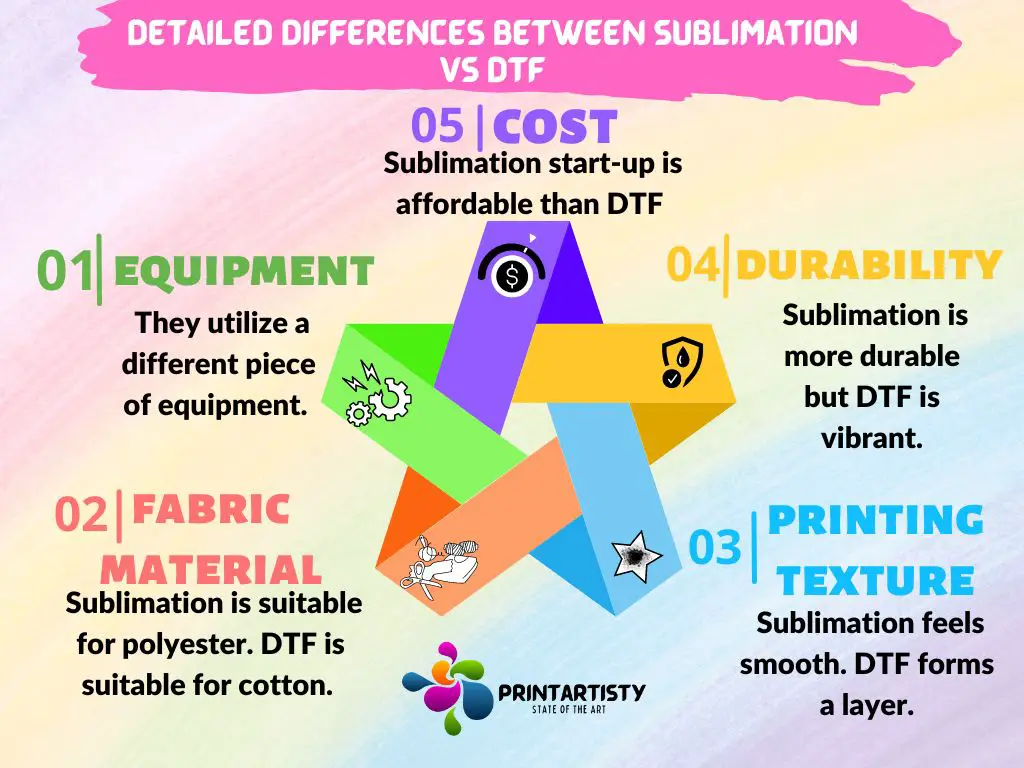

1- Use Of Equipment

Sublimation and DTF both are different methods of printing. They actually use the heat transfer method but the way they use to transfer the design is completely opposite to each other. However, they also utilize a different piece of equipment that you cannot use as alternatives for both methods except a heat press.

Sublimation Equipment

- A Sublimation Printer

Sublimation printing can be done using an inkjet sublimation printer. However, there are various types of inkjet printers but sublimation printing requires a special line of printers that utilize piezo printheads and also those printers which can handle the sublimation ink.

Most commonly, Epson sublimation printers are utilized due to their versatility. However, t-shirt sublimation printers are also there which includes the Sawgrass and Ricoma printers.

- Sublimation Ink

Sublimation ink is a special type of ink that cannot be used in normal inkjet printers. It requires a dedicated sublimation printer to use.

- Sublimation Paper

Sublimation paper is a poly-coated transfer paper that holds the sublimation ink until it is transferred onto the substrate.

- A Heat Press

Sublimation printing also requires a heat press to get the prints transferred onto the substrate.

DTF(Direct To Film) Equipment

- A Direct To Film Printer

A direct-to-film printer is completely different from a sublimation printer. A DTG printer can also be modified in order to use DTF printing. Unlike sublimation printers, DTF printers utilize 6 color inks which also include a white color ink. A DTF printer allows printing on the transfer film which cannot be done via a normal inkjet printer.

- Transfer Film

DTF requires a PET(polyethylene terephthalate) film also referred to as DTF films made from soft plastic to print on them. They are available in a wide range. Mainly, there are two types of DTF films for different purposes. One is for commercial use and the second one is for small businesses. Usually, rolls are used for commercials and Cut-sheets are used for small businesses.

- Textile Inks

There are DTF printing inks out there that are utilized with DTF printers available in CMYK. However, white ink is used as a base color on the substrate on which the design is printed.

- Adhesive Powder

While the printing film requires an adhesive powder that plays the role of glue. Once the image is printed then the powder is poured to cover the printed image on the film and is cured with heat. Again, when the film is heat pressed on the fabric, that adhesive powder helps to bind the ink on the substrate.

- A Heat Press

While DTF also involves a heat press similar to the sublimation to get the images transferred. However, you can use a heat press as a curing machine for melting the adhesive powder on the film.

2- Printing Fabric Material

Sublimation is excellent for printing white-color garments and polyester fabric. Moreover, sublimation can also be used to print synthetic fibers like plastic, nylon, Teflon, ceramics, etc. But, sublimation cannot be utilized on black color fabric or cotton material.

On the other hand, DTF can be also used for synthetic fibers too. But, DTF is one step ahead of sublimation because you can also print cotton and black color fabric with ease. There is no limitation on color and fabric material in the DTF process. Additionally, sublimation cannot print white ink as DTF printing does.

Check here Pigment ink vs sublimation ink

3- Printing Texture

Sublimation provides a smooth texture because it completely adheres to the fabric or substrate. Even if you touch the substrate, your fingers won’t feel a layer over the top.

Besides, DTF that is applied over the top of the fabric leaves a layer due to adhesive powder. DTF seems to be crisper and rich-hued than sublimation because it is laid down on the top rather than absorbing ink into the fabric so the colors will feel vibrant over the top.

4- Durability

While sublimation is more durable than DTF because it won’t peel off or crack. However, DTF may be prone to cracking or fading if you wash them with chemical detergents.

5- Cost

While DTF printers are more expensive and are used on a commercial basis. A DTF printer can cost you around $4000 to $5000. However, sublimation will require $2500 including a sublimation printer and other accessories.

Sublimation Vs DTF: Which is better?

Depending upon your personal preferences, you can choose a method accordingly. If your business is specialized in white color garments or polyester fabric then sublimation is a perfect choice for you. On the other hand, if you want to sell on the commercial level then DTF is a good option for you. But remember to keep the pricing difference in mind. Also, DTF is versatile that can be used on every type of fabric.

Advantages of sublimation

Disadvantages of sublimation

Advantages of DTF

Disadvantages of DTF

Frequently Asked Questions (FAQs)

Can I use sublimation ink for dtf?

The answer is no! You cannot use sublimation ink for DTF. Both printing methods use different types of ink. Sublimation inks can only be used with sublimation printers. DTF printers cannot handle the sublimation ink. And if you use sublimation ink with DTF printers then it will result in damage to the printer or ink bleeding on the paper.

What ink is used for DTF transfers?

DTF inks are water-based textile inks that can be used with Epson desktop printers too.

Conclusion

So we have defined both methods thoroughly to get confusion and doubts cleared. The fundamental differences are clear between sublimation and DTF. They both are different processes and require different printers and transfer papers. Sublimation is more durable but DTF is more vibrant. You can choose to kick-start the process according to your preferences.